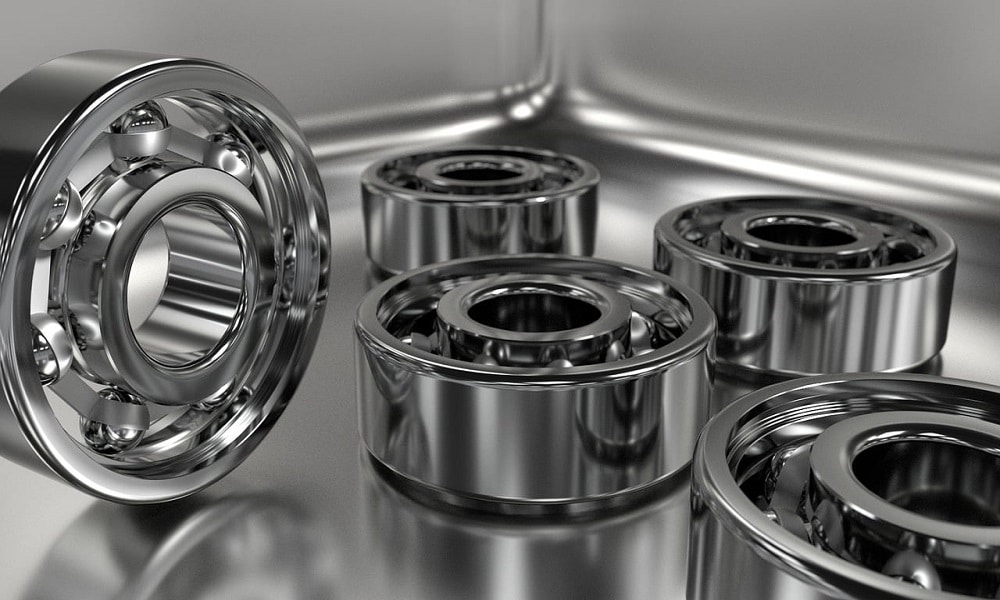

In the fast-paced world of industrial manufacturing, bearings serve as silent champions, ensuring machinery operates seamlessly. Across Australia’s manufacturing landscape, these critical components protect equipment from wear and tear, reduce unexpected downtime, and keep production lines moving efficiently. From mining to food production, bearings play a crucial role in sustaining operational excellence and ensuring businesses meet production targets without costly interruptions.

The Link Between Quality and Efficiency

The quality of a bearing directly influences the performance of the machinery it supports. High-grade bearings are crafted using superior materials and precise engineering, making them more durable and efficient.

When machines are equipped with premium components, they experience less friction, stay properly aligned, and operate more smoothly. The result is a noticeable reduction in energy usage, extended equipment lifespan, and improved reliability. Australian manufacturers striving for operational efficiency can benefit significantly from investing in quality bearings.

Beyond basic functionality, the material composition of bearings affects their performance under different conditions. For instance, stainless steel bearings resist corrosion, making them ideal for marine and food processing applications, while ceramic bearings are lightweight and capable of withstanding extreme speeds and temperatures. Understanding these variations ensures that manufacturers select the best option for their industry needs.

Factors to Consider When Choosing Bearings

Choosing the right bearings goes beyond simply finding one that fits. It requires a careful evaluation of performance under real-world conditions. The forces a bearing must withstand during operation determine whether it will last or fail prematurely. If a bearing is not up to the task, excessive stress can lead to expensive and disruptive failures.

Speed is another key aspect to consider. Fast-moving machinery demands bearings that are manufactured with exceptional precision and supported by effective lubrication to reduce friction and heat build-up. Neglecting these factors can lead to overheating, increased wear, and reduced lifespan.

Temperature conditions must also be taken into account. Australia’s diverse climate, ranging from scorching summer heat to freezing winter conditions, places additional stress on machinery. Bearings must be able to withstand these environmental extremes while maintaining consistent performance. For example, high-temperature bearings with special coatings and advanced lubricants can ensure smooth operation in demanding applications such as mining or heavy industry.

Proper Installation and Fitment: A Critical Step

Even the highest-quality bearing will fall short of its potential if improperly installed. Correct alignment, preload settings, and mounting techniques are all critical to ensuring bearings perform as intended.

A poorly installed bearing can lead to misalignment, excessive vibration, and premature failure. Skilled technicians are essential for the correct installation and alignment of these components. Investing in professional installation not only saves time and money in the long run but also provides peace of mind, ensuring machinery runs smoothly and efficiently.

Regular Maintenance for Smooth Operation

Maintenance is the foundation of bearing longevity. Regular checks on factors such as operating temperature, vibration, and lubrication help identify potential issues before they escalate. Implementing a proactive maintenance plan ensures bearings remain in peak condition and prevents unplanned equipment downtime.

A scheduled maintenance approach, rather than a reactive one, protects investments and reduces operational risks. Predictive maintenance strategies, such as vibration analysis and thermal imaging, allow maintenance teams to detect early warning signs of bearing wear and address them before they result in costly breakdowns.

Lubrication is particularly important. Insufficient or improper lubrication can cause bearings to overheat, leading to increased wear and eventual failure. Selecting the correct lubricant and applying it at recommended intervals significantly extends the life of bearings and improves machinery performance.

The True Cost of Ownership

When evaluating bearings, the focus should not be limited to upfront costs. Premium bearings may have a higher initial price, but their extended lifespan and reliability often lead to significant savings in the long run.

Reduced maintenance needs, fewer replacements, and less downtime contribute to lower total ownership costs. Businesses that prioritize short-term savings by opting for cheaper bearings may find themselves spending more over time due to frequent failures and associated operational disruptions. Investing in high-quality bearings ultimately results in improved productivity and cost efficiency.

Spotting Early Warning Signs

Being vigilant about the condition of bearings can prevent small issues from becoming major problems. Unusual noises, increased vibration, or rising operating temperatures often signal that a bearing is nearing the end of its life.

Addressing these signs promptly allows maintenance teams to plan replacements during scheduled downtime, avoiding the chaos of unexpected breakdowns. Neglecting these warning signs can lead to catastrophic equipment failures, resulting in costly repairs and production losses.

The Value of a Trusted Supplier

The right bearing supplier is as important as the bearings themselves. A reliable supplier offers more than just products; they provide expertise and guidance.

From selecting the appropriate bearing for specific applications to offering insights on installation and maintenance, a dependable partner ensures businesses get the most value from their investment. When choosing a supplier, look for one with a proven track record, a comprehensive product range, and a deep understanding of Australia’s industrial landscape. Local suppliers with experience in Australian conditions can provide invaluable recommendations tailored to the unique needs of the market.

The Future of Bearing Technology

As technology advances, so too does bearing design. Modern bearings are increasingly incorporating smart features, such as embedded sensors that monitor temperature, vibration, and lubrication levels in real-time. These innovations enable predictive maintenance, allowing manufacturers to address issues before they cause disruptions.

Self-lubricating bearings and hybrid designs combining ceramic and steel elements are also gaining popularity due to their extended lifespan and reduced maintenance requirements. As the industry moves toward automation and efficiency, these advancements will continue to shape the future of industrial manufacturing in Australia.

Maximizing Reliability and Efficiency

Quality bearings are the foundation of reliable, efficient operations. By prioritizing high-grade components, ensuring proper installation, and staying on top of maintenance, Australian manufacturers can achieve smoother operations and greater productivity.

Partnering with experienced suppliers further enhances these outcomes, offering the support needed to optimize bearing applications for long-term success. As the industry evolves, staying informed about the latest bearing technologies and best practices will allow businesses to maintain a competitive edge while reducing operational risks.

Conclusion

Bearings are small components with a massive impact on industrial performance. Whether in mining, manufacturing, or food processing, selecting the right bearings and maintaining them properly ensures seamless operations and cost savings. By investing in quality bearings, working with knowledgeable suppliers, and adopting proactive maintenance strategies, Australian manufacturers can maximize efficiency and equipment longevity, securing a stronger future for their operations.