The Internet of Things (IoT) is bringing a digital revolution to the manufacturing industry. By connecting machines, sensors, and systems through the internet, manufacturers can now collect real-time data to improve efficiency, reduce downtime, and streamline operations. As digital technology and innovations like AI in healthcare are changing other sectors, IoT is becoming a powerful tool for smarter and faster manufacturing.

What Is IoT in Manufacturing Digital Revolution?

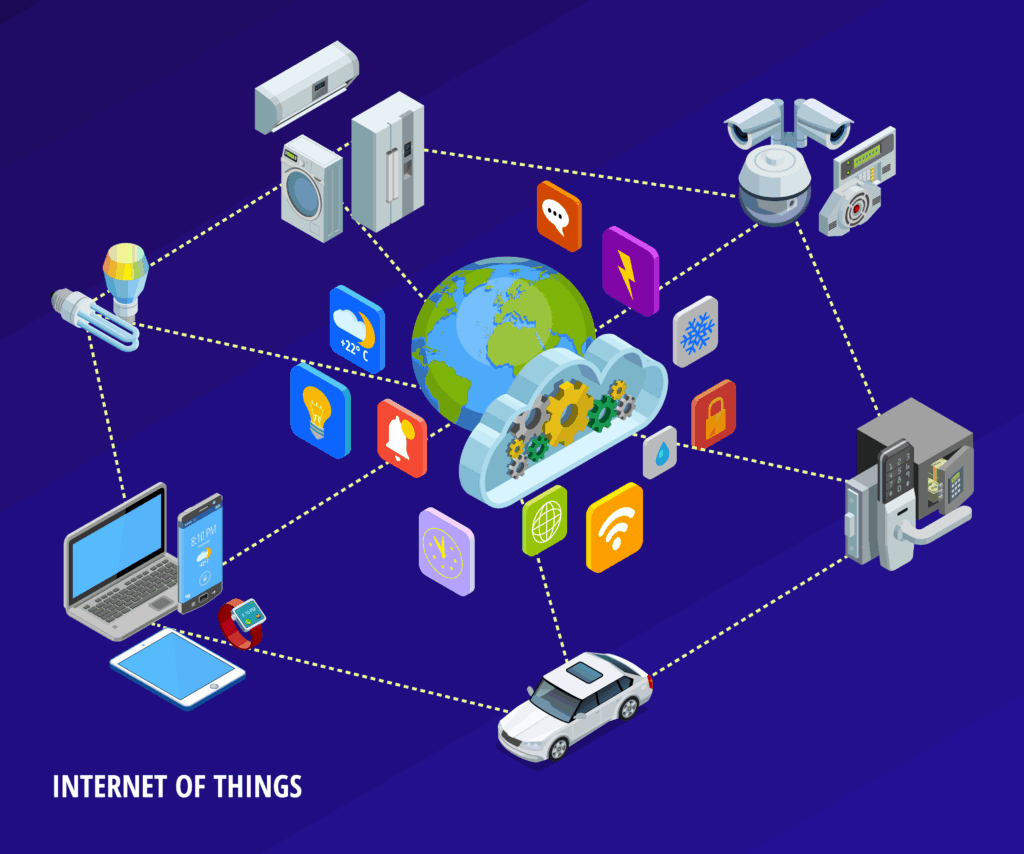

IoT in manufacturing, often called Industrial IoT (IIoT), refers to the use of internet-connected devices to monitor and manage industrial operations. These devices collect and send data to help manufacturers make better decisions, reduce waste, and maintain consistent product quality. From machine sensors to automated systems, IoT helps factories become smarter and more productive.

Benefits of IoT in Manufacturing

1. Real-Time Monitoring

IoT allows continuous monitoring of machinery and equipment. If a machine starts acting abnormally, the system can send alerts immediately. This helps prevent breakdowns and keeps production on track.

2. Predictive Maintenance

With the help of sensors, manufacturers can detect early signs of equipment issues. This means machines can be serviced before they fail, reducing downtime and maintenance costs.

3. Increased Efficiency

IoT helps automate routine tasks, optimize production schedules, and manage energy usage. These improvements lead to higher productivity and lower operational costs.

4. Better Inventory Management

IoT devices can track inventory levels in real time, ensuring materials and products are always available. This reduces delays and avoids overstocking.

5. Quality Control

Smart sensors can monitor product quality throughout the production process. If something goes wrong, it can be detected and corrected quickly.

6. Improved Worker Safety

IoT can detect unsafe working conditions, such as high temperatures or harmful gases, and alert workers before accidents happen.

How Digital Technology and AI Work with IoT Manufacturing?

IoT doesn’t work alone. It is supported by other digital technologies like AI, cloud computing, and big data. In healthcare, AI is used to detect diseases early. In manufacturing, AI can analyze the huge amount of data from IoT devices to predict problems, suggest improvements, and make decisions faster than humans. Cloud platforms help store and manage this data securely, while edge computing allows faster processing near the source.

Real-World Examples of IoT in Manufacturing

Smart Factories: Many companies now use smart sensors and connected machines to monitor performance and improve output. These factories adjust operations in real time to avoid delays and waste.

Energy Management: Factories use IoT systems to monitor and reduce energy consumption, helping both the environment and their budget.

Common IoT Challenges in Manufacturing

While IoT offers many benefits, there are some challenges too:

- High Initial Costs: Setting up IoT systems can be expensive, especially for small manufacturers.

- Data Security: With more connected devices, the risk of cyberattacks increases. Strong security measures are necessary.

- Technical Complexity: Managing and analyzing large amounts of data requires skilled staff and proper training.

- Integration Issues: Connecting IoT with older machines or different systems can be difficult.

What Really Helps IoT Work Better in Real Life?

To get the most out of IoT in manufacturing:

- Start small with pilot projects

- Train staff to understand and use IoT tools

- Invest in data security

- Work with reliable technology partners

- Monitor performance regularly and adjust as needed

Conclusion

IoT is transforming manufacturing by making it smarter, faster, and more efficient. With the support of digital technology and AI, it helps improve product quality, reduce costs, and increase safety. Though there are some challenges, the benefits make IoT a powerful step toward the future of manufacturing. As more companies adopt IoT, they will gain a competitive edge in the digital age.

FAQs

1. What is IoT in manufacturing?

IoT in manufacturing refers to using internet-connected devices to monitor and control machines, improve production, and reduce waste.

2. How does IoT help reduce downtime?

By using sensors that monitor machines, IoT can detect issues early and send alerts so problems can be fixed before a breakdown occurs.

3. Can small manufacturers use IoT?

Yes. Small manufacturers can start with simple, low-cost IoT solutions and expand as they see benefits.

4. Is IoT safe to use in factories?

Yes, but strong cybersecurity is important to protect data and prevent system attacks.

5. How does AI support IoT in manufacturing?

AI analyzes the data from IoT devices to find patterns, predict issues, and make decisions that improve operations.

6. What industries use IoT in manufacturing?

Automotive, electronics, food and beverage, and pharmaceuticals are some of the top industries using IoT.

7. How can IoT improve product quality?

Sensors track product quality in real time, helping spot and fix issues quickly during production.

8. What is predictive maintenance?

It’s when IoT helps identify early signs of machine problems so maintenance can be done before a breakdown happens.

9. Do IoT systems need internet all the time?

Most do, but some use edge computing to work even with limited internet by processing data locally.

10. What is the future of IoT in manufacturing?

IoT will continue to grow, with more smart factories, better automation, and deeper integration with AI and digital tools.

Author Bio:-

Ritesh Dave is the Co-Founder & Director – Sales at Synoverge Technologies. A seasoned IT outsourcing leader with 20+ years of global experience, he excels in business development, client engagement, and building high-value strategic partnerships.