Micro-electromagnetic system MEMs is a technological process used to generate tiny integrated systems or devices that combine electrical and mechanical components that benefit industries such as space, medicine, and innovation. From medical app design, to nanotechnology in medicine, innovation is the drive behind improved health, and improvement.

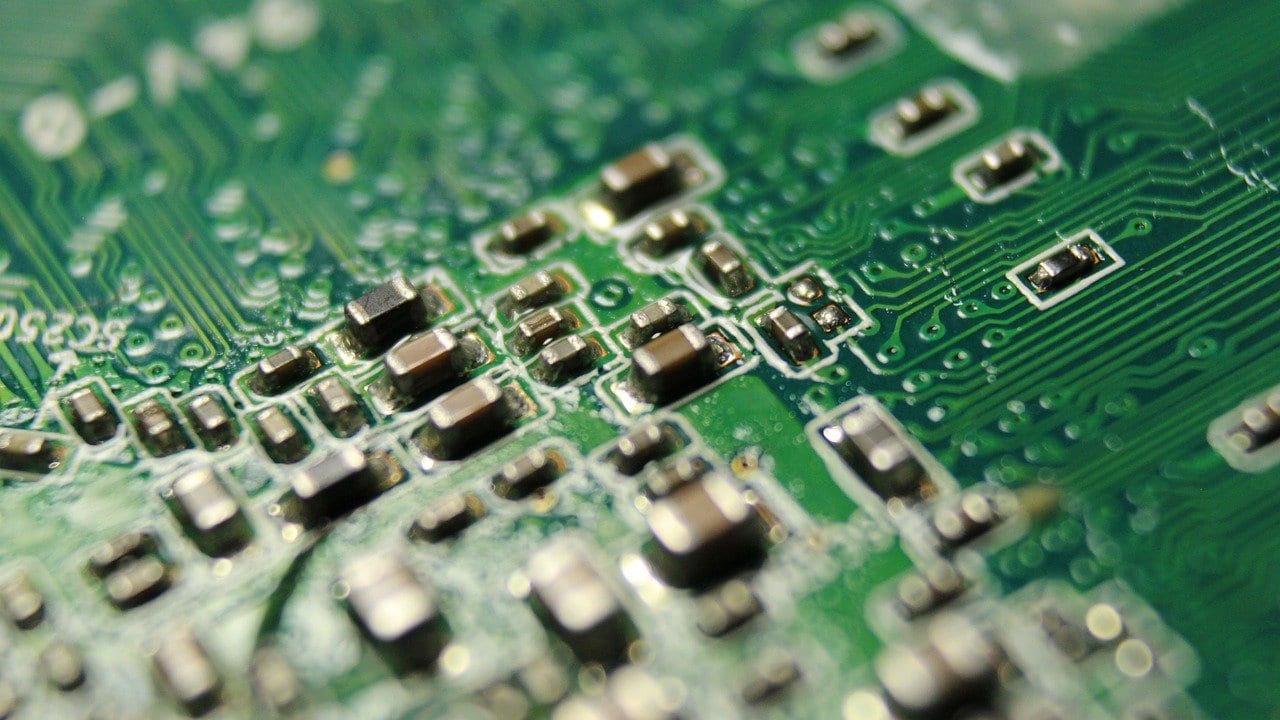

MEMS fabrication is made using integrated circuit batch processing procedures. Its size can range from micrometers to millimeters. MEMS devices have the power to control, sense, and actuate on the microscale and produce impacts on the micro scale.

The following are some of the advantages of using MEMS Devices:

- Minimal size, volume, and mass

- Batch fabricated in large arrays

- Easy to incorporate into systems or modify

- Can be highly resistant to shock, vibration, and radiation

- Low power consumption

- Reduced cost

- Small thermal constant

- Enhanced thermal expansion tolerance

MEMS Manufacturing Materials

Silicon

Silicon is the component used to craft numerous integrated circuits applied in electronic devices in the current industry. Silicon is suitable for a wide usage of MEMS uses, such as availability, cheaper cost, high-quality materials, the power to integrate electronic functionality, and the economies of scale. It also possesses substantial benefits from its material features.

Metals

Metals can also be used in the production of MEMS elements. Although metals do not possess some of the benefits exhibited by silicon in terms of technological features, they can display high-reliability levels when fully utilized.

Metals can be deposited by evaporation, sputtering, and electroplating processes. Some of the most used metals include nickel, gold, copper, aluminum, titanium, tungsten, chromium, silver, and platinum.

Polymers

Although the electronic industry offers scale economies for silicon production, crystalline silicon is a costly and complex material to generate. On the other hand, polymers can be generated in large volumes and with several material features.

MEMS devices can be produced from polymers through procedures like molding, injection, stereolithography, and embossing. They are suitable for microfluidic applications like one-use blood testing cartridges.

Ceramics

The nitrides of aluminum, silicon, silicon carbide, titanium, and other ceramics are increasingly used in MEMS production due to the beneficial combination of material features. AIN crystallizes in the wurtzite design hence exhibits piezoelectric and pyroelectric features, enabling sensors to possess sensitivity to shear and regular forces.

On the other hand, TiN displays high large elastic modulus and high electrical conductivity, enabling it to implement MEMS actuation outlines with ultrathin beams.

MEMS Manufacturing Technologies

Surface micromachining

This applies deposited layers on the substrate surface as the structural materials, instead of using the substrate.

Bulk micromachining

This is the oldest prototype of silicon-based MEMS. The entire thickness of the silicon wafer is used for creating micro-mechanical structures.

High Aspect Ratio (HAR) Silicon Micromachining

Both surface and bulk silicon micromachining are applied in the commercial production and micromanufacturing of ink-jet nozzles, sensors, and other devices. However, in several cases, the discrepancy between these two has reduced.

Thermal oxidation

The application of the etch-less process is habitually applied to manage the size of nano-scale and micro components. This technique mainly depends on silicon oxidation, as explained by the Deal-Grove model.

Some applications of MEMS include:

- Ink-jet printers

- Accelerometers in modern cars

- Inertial measurement units

- Accelerometers in consumer electronic devices like game controllers

- MEMS barometers

Technology Involved

Micro Electro-Mechanical Systems (MEMS) utilize mini-dimensional mechanical and electrical elements that are fabricated from micrometer to several millimeters. The two systems work together to ensure that the microsystem correctly handles the assigned tasks. The size of the MEMS should not fool you. It can drive macroscale applications in the industry, making it the go-to device for precision and performance. In this article you will learn the following:

- Purpose of MEMS technology

- Types of technologies used

- Components of MEMS technology

- The properties of the materials used in the fabrication

Purpose of MEMS Technology

MEMS miniature nature allows it to be used in different industries ranging from the medical, especially in medicines that require pressure sensors, automobile, communications, and biotechnology sectors. The mobility of the system’s elements varies depending on the functionality of the system. The system’s micro-elements are used to convert energy to initiate the specific tasks assigned for the system.

The challenge in submillimeter manufacturing of the systems is maintaining accuracy and longevity during its service. There are proven technologies that increase precision by using micromachining equipment and processes. The microsystems’ delicate nature makes them vulnerable to wear and tear; therefore, there are additional measures taken to ensure the longevity of the systems, like using protective chemicals for surface protection.

Types of Technologies in MEMS

The functionality of the MEMS defines the type of technologies that you will use in its manufacturing. Different functions will require different elements and technologies, ranging from the sensors, actuators, and the structure. Some systems will require additional nanofabrication for a finer structural and functional system.

The trigger in MEMS determines the types of technology it uses: capacitive and ohmic technology. The former uses sensing elements, while ohmic technologies use change in the electrostatic field for a trigger to initiate different tasks.

Components of MEMS Technology

There are various components in the MEMS:

Microsensors

There are different types of electronic sensors for sensing the change in temperature, pressure, radiation, chemical, or magnetic forces. These changes in conditions will then act as the trigger for the next function in the sequence.

Micro actuators

Actuators act as transducers: they transform electrical to mechanical energy to initiate the system’s assigned task.

Microelectronics

Microelectronics contains the basic IC (Integrated Circuit) structure of the system—it is responsible for the system’s different commands (how and when the system will initiate specific functions). It utilizes programs that mesh the different events to ensure the proper functionality of the system.

Microstructures

The microstructure is the mechanical housing of the system that protects it from external interference and damages.

The Properties of the Materials Used in Fabrication

MEMS technology uses glass substrates or silicon materials in its submillimeter manufacturing. It is easier to manipulate these materials in etching, wafer bonding, laser, micro, or nano-machining methods. Its light nature allows different elements to be inserted using the top-down or bottom-up fabrications methods.

MEMS, nanosystems, and ICs play a significant role in increasing the systems’ efficiency in the different fields. The advanced research and technology only go to show its importance in the industry. Therefore, you can only expect greater systems with added benefits.