Diving into the world of 3D printing with ASA filament can be both exciting and challenging. ASA filament is known for its strength and UV resistance, making it perfect for outdoor projects. However, getting the best print quality with ASA requires some know-how.

ASA Filament’s Properties and Applications in 3D Printing

- UV Stability: Resists fading and yellowing.

- Durability: Holds up under stress.

- Chemical Resistance: Withstands various chemicals.

- Temperature Resistance: Functions well in changing climates.

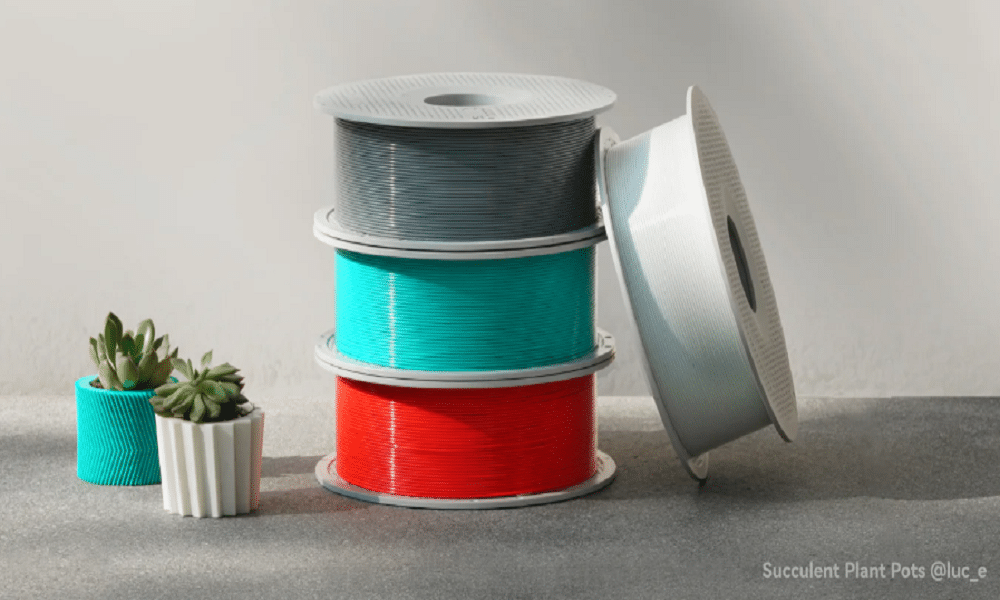

Key Features of Bambu Lab ASA Filament for High-Performance 3D Printing

Bambu Lab ASA filament stands out for its precise quality and consistency. One time, while printing a prototype for an outdoor fixture, I noticed how the filament maintained dimensional accuracy even with varying temperatures. Here are some standout features:

- UV Resistance: Prevents fading and maintains vibrant colors.

- Durability: It withstands stress and is perfect for outdoor uses.

- Chemical Resistance: Ideal for prints exposed to harsh chemicals.

Each quality enhances performance while maintaining ease of use.

Why Choose ASA Filament

ASA filament stands out because of its strong performance attributes. From exceptional durability to robust weather resistance, it’s the go-to choice for outdoor projects. Here’s what makes it shine:

Durability

ASA filament excels in durability, handling stress like a champ. When I printed a garden tool holder, it stood up to constant use. Thanks to its strength, ASA has your back with projects demanding longevity. It marks toughness, resisting wear and tear over time, making it perfect for long-lasting applications.

Weather Resistance

ASA filament thrives in tough weather conditions. Once, I left a print outdoors for months, and it remained intact. High-temperature resilience and resistance to chemicals make it perfect for objects exposed to the elements. It’s the right pick for outdoor installations where the weather is unpredictable.

UV Protection

ASA filament offers excellent UV protection, keeping prints from fading. I noticed that my ASA-printed outdoor decorations retained color without yellowing. This UV stability means it works well under sunlight, ensuring vibrant prints that maintain their original color. It is ideal for outdoor projects needing a long-lasting appearance.

Tips on How to Achieve the Best Print Quality with ASA Filament

Experimenting with ASA filament in 3D printing can be rewarding. It’s all about tuning the settings and refining techniques to get that perfect print.

Optimal Printer Settings

Nozzle Temperature

Maintaining the correct nozzle temperature is essential when printing with ASA filament. Set it between 240°C and 260°C for optimal results. I discovered that 250°C worked perfectly for my outdoor lantern project. It ensured strong fusion and a smooth finish, making it durable enough to withstand weather exposure and prolonged use outdoors.

Bed Temperature

ASA filament performs best with a warm bed. Set the bed temperature between 90°C and 110°C to ensure proper adhesion and minimize warping during printing. This range helps the filament stick to the print surface, resulting in smoother, more consistent prints and reducing the likelihood of edges lifting or distorting.

Print Speed

Slower print speeds of around 30-50 mm/s are recommended for smoother finishes when printing with ASA filament. If faster speeds compromise quality, reduce the speed accordingly. Slower printing helps improve layer bonding, reducing imperfections and ensuring a more polished final product, especially for detailed or complex designs.

Warping Prevention

Warping can be a challenge when printing with ASA filament. To combat this, use an enclosed printer to maintain consistent temperatures. Applying adhesives like PEI sheets or glue sticks on the print bed can significantly improve bed adhesion. This method keeps my models flat and stable throughout printing, reducing the risk of warping.

Proper Layer Height and Wall Thickness

Choosing the right layer height and wall thickness is crucial for print quality. For finer details, use a layer height of 0.1-0.2 mm. Thicker walls, around 1.2-1.5 mm, offer enhanced strength and stability, making them especially suitable for outdoor applications where durability is key. This balance ensures a sturdy yet detailed 3D print.

Support Structures

Supports are crucial for printing overhangs. Set them at a 45-degree angle and adjust the density to balance stability and easy removal. Using a lower density allows for simpler cleanup while providing enough structure support. This approach ensures that your prints are well-supported without making post-processing too difficult.

Post-Processing Techniques

After printing, ASA filament benefits from sanding and chemical smoothing. Use fine-grit sandpaper for a polished look, or apply acetone vapor for a smooth finish. A quick acetone wipe can enhance the print’s appearance, making it more appealing without losing detail.

Conclusion

The first time I used ASA filament, I struggled with warping. After adjusting the bed temperature and print speed, my prints improved greatly. Focus on these settings for smooth printing. Keep experimenting with temperatures and techniques to improve output consistently. Consider post-processing to enhance final prints.