For manufacturers, ensuring the quality and safety of their products is always a top priority.

One crucial aspect of this is leak testing, which can prevent catastrophic consequences such as contamination or explosions.

As an expert in the field, I have seen firsthand the damage that can result from even the smallest leaks in packaging.

That’s why I’m passionate about spreading awareness of the importance of leak testing in manufacturing.

Whether you’re a business owner or a concerned consumer, this article will help you understand why leak testing is important in manufacturing.

Key Takeaways

- Leak testing is essential to ensuring product quality and safety.

- Leaks in packaging can lead to catastrophic consequences such as contamination or product loss.

- Understanding the risks of not properly testing packages is important.

What is Leak Testing?

Leak testing is one of the most important steps in ensuring the quality of your products, and is a major way to improve your business’s manufacturing processes.

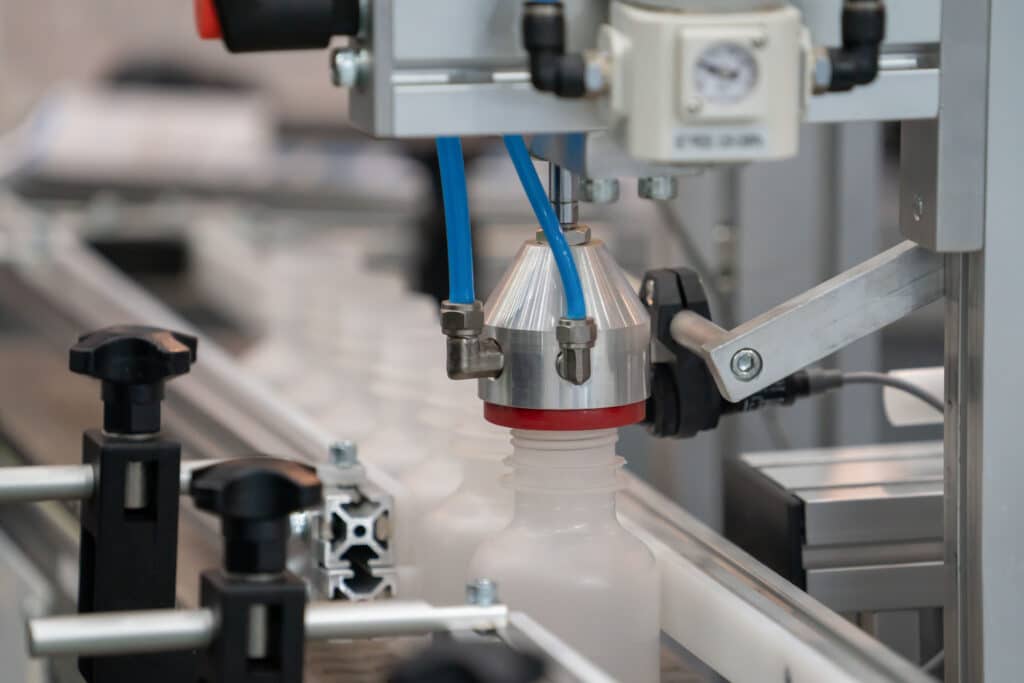

It involves using specialized tools, known as leak detectors, to identify potential leaks before they become catastrophic failures.

With the ability to detect leaks at the source and during transport, these tools give you peace of mind knowing that your products are safe and secure.

Whether working with glass jars, plastic bags, or corrugated boxes, a high-quality leak detector can help you identify potential issues and prevent costly recalls or customer complaints.

Types of Leak Testers

Once you’ve decided to invest in a leak tester, it’s important to understand the different types available.

Let’s look at the three main types of leak testers.

Underwater/Bubble Leak Testers

Submerging your packaging in water to detect leaks might seem outdated, but bubble leak testers remain a popular method for many industries.

By observing visible bubbles that arise from the leak location, operators can quickly and easily identify where potential issues may lie.

However, this method isn’t foolproof.

Bubble leak testers are notorious for missing small leaks and relying on human judgment, which isn’t always accurate.

So while bubble leak testers might be popular, they might not be the best option for your specific needs.

Pressure Decay Leak Testers

When it comes to ensuring the integrity of packages, pressure decay leak testers are an excellent option to consider.

- By creating a vacuum within the test chamber and measuring pressure decay with a differential pressure transmitter, these testers provide a highly sensitive, quantitative method for detecting leaks.

- Moreover, pressure decay testing is operator-independent, so it’s highly reliable for detecting even the smallest leaks.

To ensure your packages’ safety and quality, consider the benefits of pressure decay leak testing.

Principle of Pressure Decay Leak Test

Leaky packaging is inconvenient and can lead to damaged goods or potential safety hazards.

Fortunately, with a pressure decay leak test, operators can quickly and easily identify any faults in the packaging.

By creating a vacuum environment and monitoring the rate of pressure decay towards atmospheric pressure, any leaks can be detected and dealt with accordingly.

It’s important to note that the passing standard for this test will vary depending on the type of packaging used and the stress it’s expected to experience throughout the supply chain process.

Pressure decay leak testing can save time, money, and lives.

Importance of Leak Testing

Package leak detectors are a vital tool for monitoring the integrity of packages and containers when transporting goods.

It is usually used by businesses that need to keep track of their shipments to ensure that the contents inside are in good condition before they reach their final destination.

Package leak detectors can help protect against losses due to package damage or loss, which is why most shipping companies in the USA invest in this technology.

Let’s look at some of the most important benefits of package leak testing.

Maintains Product Stability

Ensuring product stability is key for any business.

Nothing can damage a company’s reputation more than releasing faulty products into the market. This is where leak testing comes in as a crucial step in the manufacturing process.

- This procedure involves identifying potential leaks in the product, thereby preventing damage or contamination.

- Also, manufacturers can ensure that their products meet the required standards and specifications through leak testing.

Ultimately, this ensures that consumers get the most out of their purchases and that companies can maintain their reputation in the market. Therefore, leak testing is vital to maintaining product stability and ensuring the longevity of any business.

Eliminates Excessive Labor and Material

Leak testing is essential for any company that wants to avoid costly labor and material waste.

With the help of modern technology, detecting leaks has become an efficient and reliable process that eliminates the need for manual inspection.

A package leak detector fitted with an automatic temperature or pressure sensor can detect leaks swiftly and accurately, providing peace of mind for businesses that rely on their products for safe and secure transport.

Investing in leak testing systems can help organizations reduce labor and material costs and enhance their production processes.

It helps Minimize Product Loss

In production, minimizing product loss is crucial for any company. That’s where leak testing comes into play.

By detecting leaks early on, companies can save thousands of dollars in wasted resources and avoid the hassle of product recalls.

- The importance of leak testing cannot be overstated, as even the smallest leaks can result in significant product loss over time.

- Not to mention, ensuring product quality and safety is essential for maintaining customer satisfaction and brand reputation.

Investing in proper leak testing equipment and procedures may seem like an added cost, but in the long run, it can help businesses avoid major financial setbacks and ensure their products are up to par.

Aids in Protecting the Environment

Leak testing is not just important for ensuring the quality of products; it also plays a crucial role in protecting the environment.

When products that contain hazardous or toxic materials are not properly tested for leaks, it can result in harmful substances being released into the air or water.

This can have devastating effects on ecosystems and the health of both humans and wildlife.

By using leak testing methods that prioritize environmental protection, we can ensure that our products are safe and sustainable and contribute to a healthier planet.

Prevents Costly Accidents

Leak testing is crucial in preventing costly accidents that can cause a major dent in your budget.

Without proper testing, you risk losing valuable inventory or even experiencing accidents that can damage your reputation.

- A package leak detector is a quick and easy solution that can help catch leaks before they become a bigger problem.

- It allows you to save time and money by preventing costly stoppages and avoiding accidents that could lead to injuries.

Investing in leak testing can protect your business and ensure your products remain safe and secure.

Conclusion

Leak testing is an invaluable tool for any manufacturing process. It helps manufacturers maintain product standards and avoid costly labor and material waste.

It also minimizes product loss, aids in protecting the environment, and prevents costly accidents. Investing in proper leak testing systems can help businesses ensure their products are safe and of the highest quality.

With the help of modern technology, leak testing has become an efficient and reliable process that can save businesses time and money in the long run. So why not give it a try? It could be just what your business needs!

Now we’d like to hear from you; why do you think leak testing is important in manufacturing? Share your thoughts with us!