It is the mandate of business owners and managers to protect the venture’s assets through a maintenance program. The initiative handles inspection, repairs, replacement, and servicing of equipment. We cannot overstate the importance of repair and maintenance programs as companies need to integrate them into their daily operations. It is crucial in ensuring assets are in good condition and working at optimum.

Reasons to have a Repair and Maintenance Program

Efficiency and productivity are key factors to every business’s success. It cuts across all industries, and companies’ management needs to ensure their systems are fully operational. Since technology is taking over processes, it is crucial to adapt to the changes by integrating an approach to maintenance management. If there is no maintenance department, the administration needs to understand mro meaning and what is cmms program. They have to develop an actionable plan that they can implement to improve the business operations.

Every person in the company has to understand the repair and maintenance program for it to be successful. It is the responsibility of the senior and junior staff to look after the company assets. A clear chain of command in reporting problems in assets is critical for speedy action. Below are other reasons to have a repair and maintenance program;

- Improve productivity; there is increased productivity at the workplace when equipment and machines are operating at optimum. Routine maintenance of the assets reduces the risks of them being unavailable as the business will lose production time. It will cost them revenue and profits while they pay operators for the time they did not work. On the other hand, the service delivery and quality of manufactured goods improve due to high-performing workplace tools.

- Increase asset’s service life;equipment degrades over time, and it is critical to restoring them into the required standards. The initiative of taking care of assets will extend their service life. It ensures the business has a return on the investments.

- Plan for emergencies; it is beneficial for companies to have their safety systems working correctly in readiness for any eventualities. Repair and maintenance programs ensure the safety equipment is functioning in times of emergencies. A business can undergo significant losses if the tools will not be performing at the time of need.

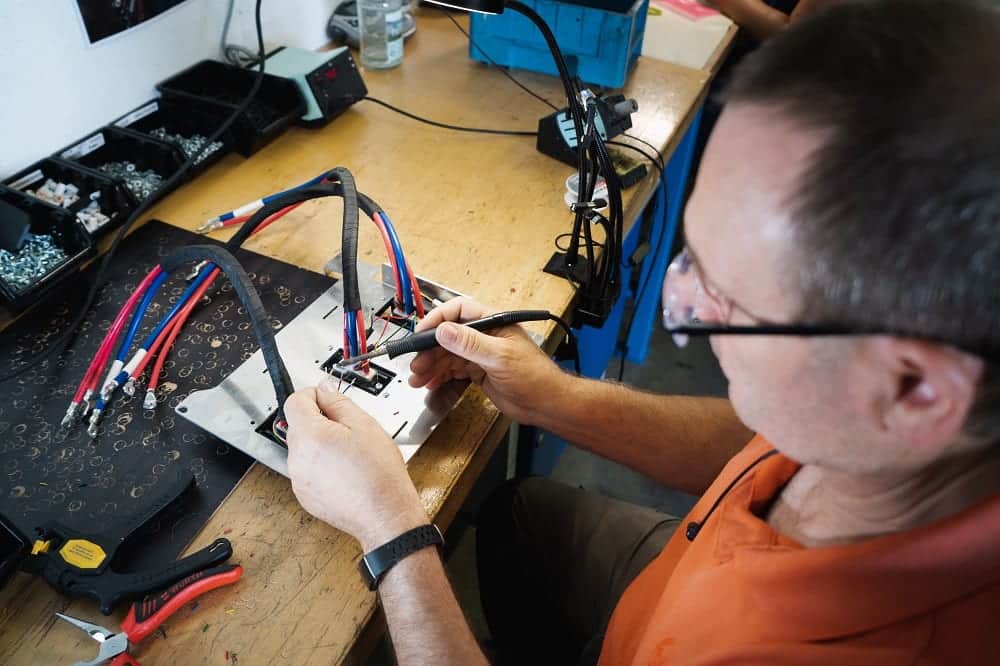

- Safety at the workplace; inspecting industrial equipment is essential in making them safe for the employees using them.It entails proper maintenance of the items and following all the set-out instructions.

Tips for an effective Repair and Maintenance Program

Here are tips that can help businesses have an effective program in repair and maintenance;

- Read the manufacturer’s manual;the industrial tools developers will include a manual with the specifications and instructions on using the equipment. It is vital to go through it to come up with a repair and maintenance program. However, the maintenance department needs to adjust the frequency of repair and maintenance according to the equipment’s usage duration.

- Frequent inspection; routine inspection of assets ensures that the company detects problems before they happen. Look at the standard time it takes for equipment to fail and inspect it twice during the projected period.

- Have a clear plan; it takes more time for technicians to conduct the inspection, repair, and maintenance activities if there is no clear way of undertaking the tasks. Time is money, and the program can break down what technicians can prioritize. It ensures the maintenance department responds in time to prevent downtime in business operations. Although the company might outsource more services, having a clear plan helps both parties.

- Skills vs tasks; a repair and maintenance plan will match functions with the technician’s abilities to handle them. The management needs to be specific when coming up with the program. They can prioritize problems that can be more costly than others.

Conclusion

CMMS softwares help organization to meet the safety standards by immaculate preventive maintenance scheduling and automatic work order activation. They also keep you alert on inspection matters by email notification. To keep smoother communication on safety protocols, the software can be used on all work orders. One must remember that preventive maintenance is much better than corrective maintenance. CMMS is often deployed as a part of organization’s expansion plan.

As a part of company’s daily maintenance routine, a cmms programme will help you to minimize downtime and interruptions in productions. Two most important factors like lesser downtime and smoother production will definitely lead to superior production value and hence better product quality. The daily usage of cmms software by incorporating it into your maintenance procedure does helps you to refine your maintenance process and effectiveness of any organization procedure. It is crucial to be realistic with the plan to avoid under or over-maintaining the company assets. The initiative saves time and money.