CNC machinery can be a blessing to any ambitious manufacturing business, but knowing which gear is the right choice for your organization is not always straightforward.

To make things easier, here are a few points to consider as you search for your perfect CNC machine from a large pool of prospective candidates.

New or Used?

The first question is whether you should order a brand new piece of equipment or instead opt for a second-hand equivalent.

If your budget is particularly tight, buying used is typically a better prospect from a financial perspective. The other good news is that you will not even need to compromise in terms of performance potential, functionality or upgradability, as modern platforms offer Haas CNC for sale at competitive prices from reputable sellers that are just as capable as new counterparts.

Another reason to buy used is that you will be able to overcome any potential availability limitations or waiting lists that can afflict new machinery.

Space Considerations

Before doing anything else, make sure that you make note of the amount of space you have available for the equipment and the nature of the space itself, especially with regards to access.

You will need to limit your search to CNC machinery that is of a size and weight that can easily be accommodated in the area you have to dedicate to it.

This can be something of a balancing act, because of course, you need to make sure that the equipment you choose is adequately powerful to meet your needs, and has a working radius that will encompass the materials you want to cut, without also being a physical burden.

Intended Applications

There are a surprising variety of CNC machine categories available, each of which has its own perks, pitfalls, and ideal use cases. Your task is to establish which will mesh with your intended applications most closely.

For example, if you are aiming to cut intricate designs into metals and woods, a CNC laser cutting machine could fit the bill. Alternatively, if you are aiming to work with sheet metals, bending, and shaping them to create larger-scale parts, a press brake might be a better choice.

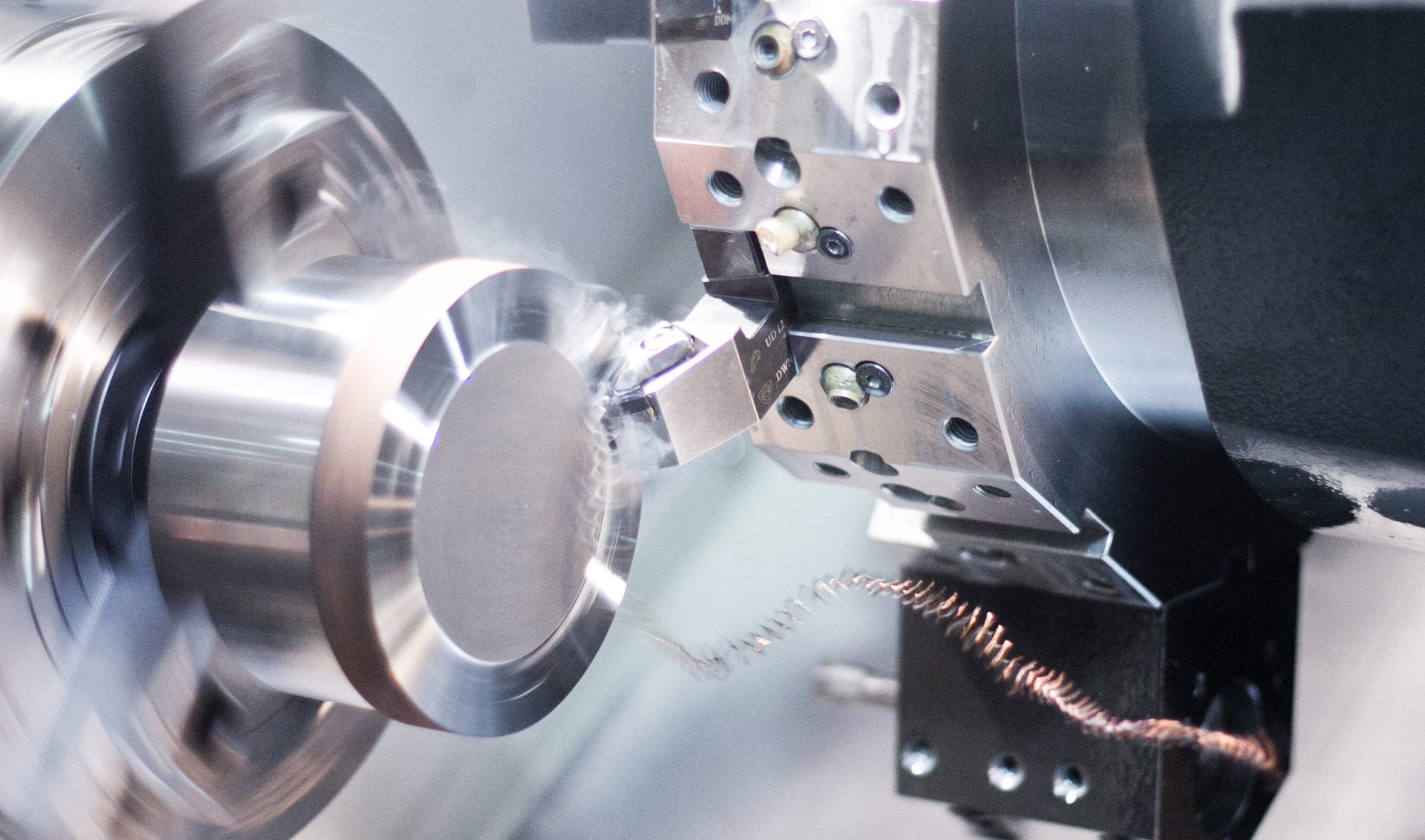

Meanwhile, working with steel or wood to fashion uniform, symmetrical parts can be best suited to a CNC lathe, or a mill.

In short, once you know what you hope to achieve with your equipment, you will be able to narrow down your options and exclude certain types of machinery while focusing only on those that are relevant.

Feed Rate

The feed rate of a CNC machine essentially describes how quickly it can work when it is put into action, so of course, a higher feed rate will mean that it is capable of completing cutting tasks in less time.

A faster feed rate can also translate into higher power consumption and thus increased running costs, so it is necessary to calculate whether this is something that can be justified financially, or whether a lower-speed machine will be adequate and more cost-effective in the long run.

Following on from this, you should also establish whether the power draw of a machine will be satisfied by your on-site services, or whether it will be necessary to make any upgrades or other investments to your infrastructure ahead of taking delivery.

Maintenance

If a CNC machine is taken out of action by a fault or the unavoidable wear and tear to its components, the resultant downtime could be costly and potentially disastrous for your business.

Because of this, you need to consider not only how easy it will be to maintain the equipment you use, but also whether or not there is even a ready supply of spare parts for a given unit that is on your most-wanted list.

Wrapping Up

Finally, when it comes to choosing CNC machinery, remember that you will likely have to make at least a partial compromise when procuring equipment, so do not hold out for some unknown ‘ideal’ example, because this will just delay your acquisition of an imperfect yet entirely adequate equivalent.

Likewise, always keep your needs at the top of the agenda and avoid being beguiled by equipment that is surplus to these requirements, and you should be on the right track.

CNC Machining Milling Metal Drilling and Cutting Processing -DepositPhotos