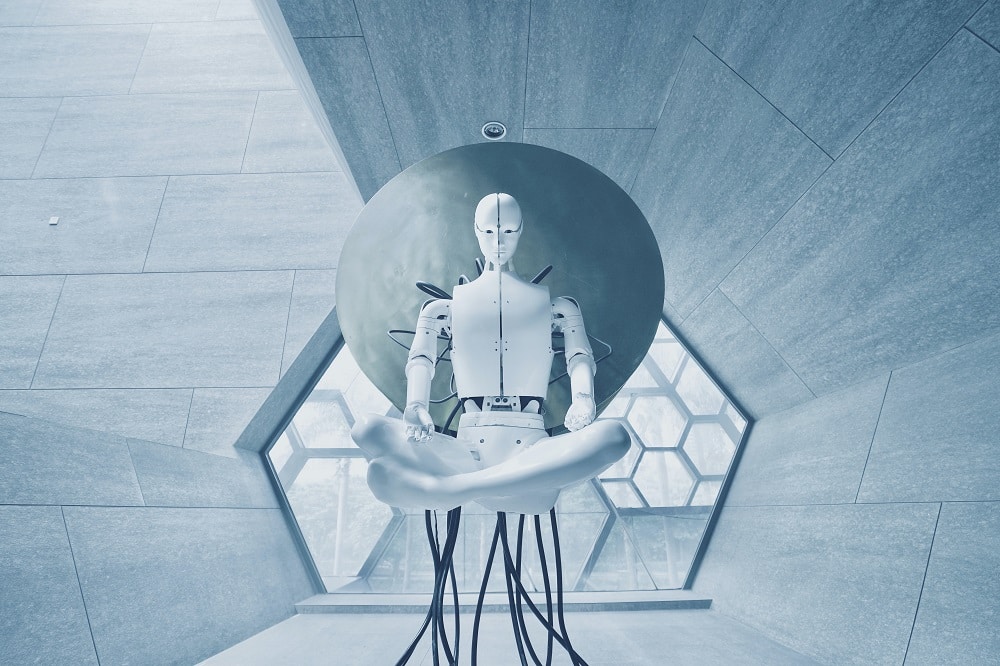

Contrary to the popular belief that movies like The Terminator have ingrained in our brains, robots are beneficial across many industries and even save human lives on a daily basis.

Robots and AI systems are becoming increasingly popular because they decrease workplace injuries, limit human errors, and keep processes moving seamlessly while reducing costs.

Let’s look at five industries where robots are making a difference.

Manufacturing

The manufacturing industry has been one of the first industries to take advantage of automation and robots; it’s a natural partnership. Robots are replacing humans as well as assisting them with their jobs.

In factories, many mundane tasks don’t take much thought with the help of machinery. Workers get bored and stop paying attention, leading to decreased productivity and more workplace injuries.

Robots are taking over repetitive and dangerous tasks. They can also work around the clock to keep production going and increase revenue while humans cannot.

Giving dangerous manufacturing tasks to robots keeps humans out of harm’s way. If something heavy falls on a robot or a robot’s “arm” gets crushed during an assembly process, it’s only a machine and not an actual employee.

In tandem, robots and artificial intelligence systems are being used to warn humans about potential dangers when they are working in manufacturing facilities. These systems can send out warning alarms or shut down machines before someone gets hurt due to equipment malfunctions.

Healthcare

In the healthcare industry, robots are leveraged to clean and disinfect hospitals and medical offices. While stocking products may sound like a trivial task to take over, doing so enables nurses, doctors, and other personnel to take more time tending to the work that requires their attention (like paperwork, writing prescriptions, making diagnoses, etc.).

Plus, robots can use UV light to disinfect areas. Humans can’t do this because UV light has adverse effects on the eyes and skin.

Robots are delivering supplies to rooms, again saving time for healthcare workers who are free to handle more significant tasks.

In the healthcare field, robots are also drawing blood. Robots are more accurate and quicker than humans. It’s better for patient care because the risk of human error is eliminated.

To limit human-to-human contact, robots act as a walkie-talkie system between physicians and patients. Small robots roll into rooms and enable a doctor to talk to a patient via a two-way speaking device. Using robots as a communication device also allows nurses and clinicians to visit more patients a day.

Food and Restaurants

One way the food industry is utilizing robots is for the safe delivery of food.

During the COVID-19 pandemic, robots were created or repurposed to help maintain a safe distance between delivery company employees and people ordering food to their homes.

The most recent Domino’s commercial showcases robots that look like miniature cars and deliver pizzas. Domino’s is testing driverless delivery to get food to customers faster, keep their employees doing the most critical jobs in stores, and keep human interaction to a minimum.

Robots are also helping the food industry during the food prepping stage. They lower labor costs and eliminate the spread of germs.

Unfortunately, when humans are part of the food prepping assembly line, germs can spread. According to the CDC, an estimated 1 in 6 Americans get sick, 128,000 are hospitalized, and 3,000 die of foodborne illness every year. When robots take over food prep and packaging, it reduces the risk of contamination, lowers costs, limits work injuries, and eliminates human error.

Military and Public Safety

Robots assist military branches and the public safety industry by detecting potential threats, conducting more mundane tasks, and gathering intel.

Drones can scan areas of land to detect any bombs or lifeforms before the military moves in.

A seafaring vessel called Sea Hunter looks like a typical boat cruising the seas, but all the while, it scans the water for enemy submarines.

On a smaller scale, robots conduct security checks. They can roam the halls when a patrol is needed, scan parking garages, document car plates, and detect any suspicious activity to report to security managers or police departments.

Mining, Construction, and Plant Operations

In the mining field, robots can do surveys to see if areas are safe to start mining. Using robots here improves employee safety because they’ll know what kind of environment they’re entering into; the robot can scout potential dangers before they affect human workers.

Robot-operated drills are being used to dig deep into the earth and sea. Automated drilling can be done overnight to keep projects on schedule and within budget.

At industrial sites like oil mining and chemical plants, robots are used to clean tanks and remove sludge from industrial tanks. The robots are controlled remotely, but other than that, no humans are involved. The traditional method of sludge removal puts humans at risk in confined spaces and exposes them to harmful chemicals.

The Future of Robotics

Industries across the globe are seeing more and more robots used every day because of their many benefits — cost savings, increased efficiency, taking humans out of harm’s way, and keeping projects on track.

Expect to see more robots as they make their way into more consumer-based industries.